Telcordia TR-332 SR-332, Bellcore Electronic Component Reliability Prediction Software. Download a free demo now.

How Had been Reliability Conjecture Strategies Developed? Dependability Predictions are usually often utilized in item design and growth as part of dependability and high quality continuous enhancements attempts. To perform a dependability prediction evaluation, a standard is employed. Each Dependability Prediction standard offers a place of numerical formulations to model and calculate the failing price of a range of electromechanical elements that make up a product or system. These equations had been built by examining a huge quantity of industry data over a long time period of period. Statistical evaluation was then used to determine the equations which best modeled the failing features of the gathered information.

- Telcordia (Bellcore) SR-332 issue 3. • NSWC handbook / procedure for mechanical equipment. •Question: Why isn’t the Telcordia predicted MTBF of a ruggedized notebook higher than the base platform?

- Telcordia Sr-332 Handbook MIL HDBK 217 Bellcore Issue 6 Telcordia FIDES standards Naval Surface Whether you need a MIL-HDBK-217F Prediction or Telcordia TR-332 Prediction of Electronic Equipment' - Even.

The factors used in the dependability calculation formulas to calculate component failure rates differ, but include data like as device ratings, temps, operating guidelines, and ecological problems. The result of a reliability prediction analysis can be the predicted failing price or Mean Period Between Failures (MTBF) of a item or program, and of its subsystems, parts, and parts. Reliability Conjecture's historic roots are in the armed forces and defense field, but over the years have long been modified and broadened for use in a wide variety of sectors. Essentially, the advantages provided by dependability prediction analyses make it an essential part of controlling and preserving dependability and high quality objectives. This content offers an overview of the nearly all commonly used reliability conjecture criteria.

How To Make use of Failure Price Predictions to Enhance Reliability Reliability Predictions offer a route to product improvement by assisting the capability to “design in” dependability. At the early design phase, Reliability Forecasts allow you to carry out an assessment of most likely failure price characteristics. By predicting failure rates, you can after that make design adjustments as required for areas of a weakness.

Panasonic the genius microwave manual. Reliability Forecasts can also be used to assess design options by taking into consideration the reliability users of the numerous options. This ability to execute design trade-off analysis with metric-based tests empowers you to create the best choices for your company. What are the Main Reliability Conjecture Criteria?

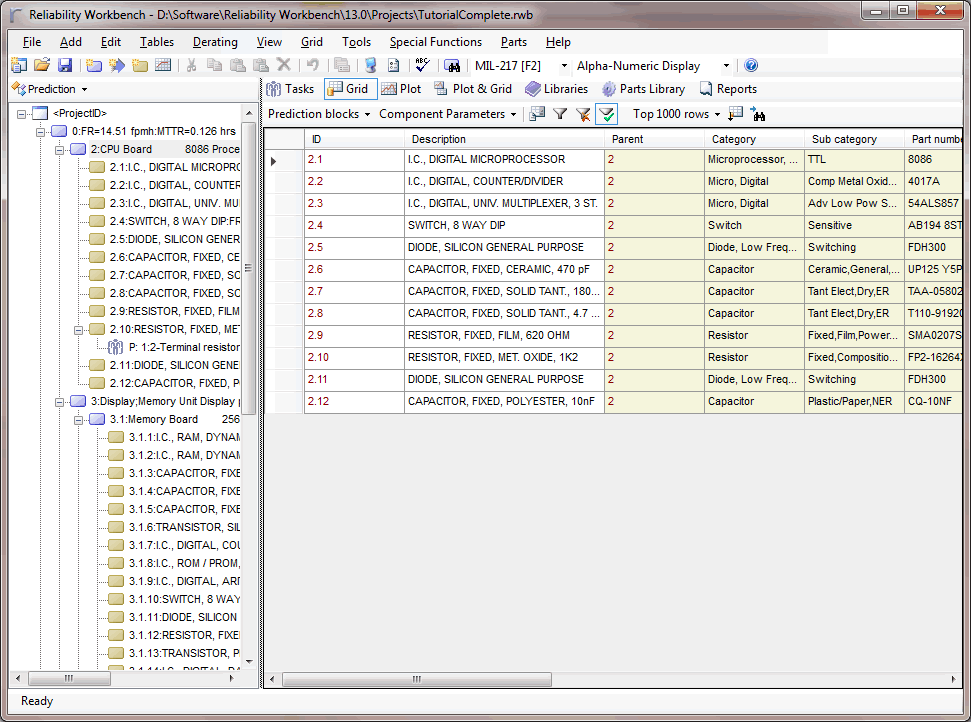

Five of the most widely utilized Reliability Prediction criteria for dependability analysis. The MIL-HDBK-217 Dependability Prediction Regular MIL-HDBK-217 is definitely one of the almost all widely recognized Reliability Conjecture criteria. It had been one of the initial models developed, and several other dependability standards available today possess their origins in MlL-HDBK-217. MIL-HDBK-217's formal name is Military Handbook: Reliability Conjecture of Electronic Devices.

It had been originally developed and published for use by the Department of Protection. Over the years there have been several improvements to the MIL-HDBK-217 record, which have resulted in thé suffix désignations in the document name: MIL-HDBK-217D and MIL-HDBK-217E See 1 for instance. The current launch of MIL-HDBK-217 is usually MIL-HDBK-217F See 2. MIL-HDBK-217 was one of the 1st models developed, and many other dependability standards accessible today have got their roots in MlL-HDBK-217.

There are two principal areas in the MIL-HDBK-217 regular: the Part Stress area and the Components Count area. MIL-HDBK-217: Part Stress Section The Part Stress area leads off the record and contains a amount of equations that predict the failure price for a broad variety of electrical elements. For instance, the formula for Microcircuits, Door/Logic Arrays and Microprocessors will be: λ g = (G 1. π Capital t + Chemical 2. π E). π Q.

π D where λ g is definitely the failing price in breakdowns/million hrs (or downfalls/10e 6 hrs, or FPMH) The elements in the equation are different operating, rated, temperatures, and ecological problems of the gadget in the program. For this over equation, the sticking with list represents the variables:. G 1 factors in the difficulty of the gadget, like as the quantity of entrance or transistors.

π Testosterone levels aspects in the normal heat and any heat range rise linked with the gadget. C 2 aspects in the package of the device, or how it is definitely produced and placed in the program, such as surface area installed and/or hermetically sealed. π Elizabeth elements in the atmosphere that the gadget is operating in, like as in space, in an aeroplanes, in the ocean, on the floor, etc.

π Q aspects in the quality of the gadget centered on how it can be procured. π M elements in how long the device has ended up manufactured The equations, the factors, and the data parameters required vary for all the various components patterned. The Component Stress area of MlL-HDBK-217 includes complete information on all thé equations and hów to assess the variables used in the équations.

MIL-HDBK-217: Parts Count Section The Parts Count reliability prediction can be useful in earlier design levels when the design is still in progress and not really all operating guidelines are identified. Parts Count number predictions perform not require as several data variables for analysis likened to Component Stress predictions. MIL-HDBK-217 Components Count analyses can end up being used as an evaluation technique, and, in general, are not really as precise as Part Stress studies. By making use of Parts Count models, you can acquire early failure rate assessments and then improve them as your item design evolves and is usually completed. The Parts Count reliability prediction is usually useful in earlier design levels when the style is nevertheless in progress and not really all operating parameters are known. For instance, the formula proven above for Microcircuits, Gate/Logic Arrays ánd Microprocessors in Parts Count can be: λ g = λ h.

π Queen where λ g is definitely a common failure rate based on a subset of details; in this example it will be structured on device technology kind, atmosphere, and gadget complexity. In many cases, Components Count can be used to start a Dependability Prediction analysis. Then, as the product design becomes even more solidified and data parameters are set up, the Parts Count conjecture is relocated over to Component Stress, maintaining all the data already got into during the Components Count evaluation.

The TeIcordia SR-332/Bellcore Regular Another widely utilized and approved Reliability Prediction standard is definitely commonly known to as Telcordia SR-332. Earlier on, Telcordia has been known to as the Bellcore regular. The complete name of the Telcordia standard is certainly Telcordia: Dependability Prediction Procedure for Electronic Products, Special Document SR-332. The Telcordia regular has also become through many up-dates and alterations, which are usually specified by the Issue Amount. Telcordia Issue 3 is certainly a generally used regular, while Telcordia SR-332 Issue 4 signifies the most recent Telcordia Reliability Prediction standard. Initially, the Bellcore/Telcordia regular was developed for make use of in the telecoms industry. Nowadays, Telcordia will be commonly used in the industrial sector.

Nevertheless, its make use of over the years has turn out to be widespread. It is definitely now utilized throughout a wide variety of sectors, like those related to armed service and defense applications. The schedule for the Telcordia versions is definitely what is certainly known to as the “Black Box Method.” Telcordia SR-332 includes equations for thé black-box continuous state failing rates of gadgets, as properly as equations for the higher confidence level and standard change of the dark box steady-state failing prices.

With Telcordia, obtainable real-world information can become utilized to further refine the estimated failure price values. In summation, somé of the special features of Telcordia include:. Versions for elements not discovered in MIL-HDBK-217, such as lithium electric batteries, hard cd disk drives, AC/DC power products, gyroscopes, and many more. Early life calculations to help analyze failing rates during initial product intro, or the early life stage, when baby mortality prices are a element. Augmenting failing rates based on information attained from laboratory check data. By factoring in check data details, your forecasts are usually weighted according to the quantity of test data you have. Augmenting failure rates centered on information attained from fielded products.

By adjusting your failure rates structured on this real-world information, your predictions will even more accurately reflect your product efficiency. The 217Plus Regular The 217Plus™ reliability prediction standard was developed by Quanterion Options. Work on 217Plus was began under Department of Protection agreements with the Reliability Analysis Center (RAC) and Reliability Information Evaluation Middle (RIAC), and has been released originally under the name PRISM. The failure rate models of 217Plus possess their origins in MlL-HDBK-217, but have improvements to include the effects of operating information, cycling aspects, and procedure marks on dependability. The standard 217Plus regular name is definitely Handbook of 217Plus Dependability Prediction Models.

An example equation for capacitórs in 217Plus 2015 Notice 1 is. Λ P =π G. π Chemical. (λ OB.

π DCO. π TO. π T + λ EB. π DCN.

π TE + λ TCB. π CR. π DT ) + λ SJB. π SJDT + λ lND where λ p will be the failure rate in failure per million work schedule hrs. 217Plus can include environmental tensions, operating user profile factors, and process marks. As with MlL-HDBK-217, there is usually a Part Count dependability prediction intended for make use of in early design when all information parameters are not however finalized, and provides a simpler technique to conjecture calculations. The Part Count section of 217Plus includes a quantity of furniture for device failure rates that are usually structured on the mixture of the atmosphere and working profile of the system.

In this case, a desk look for will provide the failing rates for your products without the need for calculations. China's GJB/z . 299 Reliability Prediction Standard China's GJB/z 299 is the most widely used Reliability Prediction standard in the extensive Chinese market. The complete title of the regular is GJB/Z . 299: Reliability Prediction Model for Electronic Equipment. Its revisions and up-dates are designated with suffix notations equivalent to MlL-HDBK-217. The almost all recent China and taiwan GJB/z .

standard is Chiná's GJB/z 299C. China's GJB/z 299 Reliability Prediction standard has its roots in MIL-HDBK-217 and has been developed to align with the procedures and devices found in China. In a similar fashion to MlL-HDBK-217, there are usually two parts of the China and taiwan's GJB/z . 299 standard: the Part Stress section and the Parts Count section.

Telcordia Standards Pdf

The Component Stress area includes full information on all thé equations and hów to evaluate the variables used in the equations. Parts Count predictions do not need as numerous data variables for analysis compared to Component Stress reliability forecasts, and are usually meant to be used in early style when not really all data parameters are usually known. Regular usage is usually to begin with a Components Count analysis and then proceed to a Part Stress prediction as real design variables are finalized.

China and taiwan's GJB/z 299 also includes an appendix for failure rate analysis for imported components, or those not manufactured in China. This allows the Chinese reliability conjecture standard to be used across a wide variety of products that include components manufactured across the world. NPRD/EPRD can become used to consist of failure rate estimates for products not modeled in the conjecture criteria.

The latest variations of these databases, NPRD-2016 and EPRD-2014, can become used alongside the conjecture requirements and function well jointly. Oftentimes, NPRD-2016 and/or EPRD-2014 can become utilized to consist of failure rate estimations for devices not patterned in the conjecture requirements. How do I select which Dependability Prediction method to use? There are usually several aspects to think about when selecting a Dependability Prediction technique to use for your analyses.

Oftentimes you may not have got a selection: there may end up being contractual needs, or the design choice may end up being selected by a techniques integrator, or it may become fixed by a dependability group. For illustration, many military and defense-based agreements will require you to make use of MIL-HDBK-217. In non-military applications, like as industrial industries like telecom, medical related devices, and consumer electronics, Telcordia is usually frequently the conjecture standard utilized. 217Plus can be used in both military and commercial applications.

In some instances, 217Plus can be seen as a following generation of MIL-HDBK-217; however, there are usually substantial differences between the two versions, as shown above, so the immediate comparison can be difficult. In many cases, 217Plus failure rate predictions are not really as pessimistic as MIL-HDBK-217. China and taiwan's GJB/z . 299 is employed almost exclusively in China, or in companies doing business with Chinese companies. The failing rate estimations from China and taiwan's GJB/z . 299 tend to be very divergent from the other standards, especially for microelectronic devices. Elements to Consider in Selecting A Dependability Prediction Regular One significant factor to consider when détermining which standard tó make use of is certainly the environments and component types backed.

For instance, MIL-HDBK-217 and 217Plus both support a broad list of conditions, whereas Telcordia supports a smaller sized collection of environments, which will not consist of military conditions like as airplane and naval. Also, the varieties of components backed in each dependability prediction specifications varies, so it can become ideal to choose the dependability prediction regular which facilitates the types of parts integrated in your style. While many of the essential device sorts are protected in all, there is certainly alternative. So it will be very best to review the devices you use in your items to notice what model to make use of. Nevertheless, you can use more than one design and experts do this for total coverage. One significant factor to consider when détermining which standard tó make use of will be the environments and part types backed.

Quality levels are furthermore various between versions. MIL-HDBK-217 consists of quality amounts for both military-level tested devices, as properly as commercial quality ranges.

Telcordia has been created for commercial applications. Benefits of Choosing TeIcordia SR-332 Telcordia can arranged an upper confidence degree on calculations and element in burn-in data; MIL-HDBK-217 does not provide these functions. Telcordia also contains the ability to alter failure price estimates centered on lab test information and/or field data; MIL-HDBK-217 will not consist of this kind of modification ability. Additionally, Telcordia consists of the capability to compute an infant mortality failure rates. However, some reliability prediction software packages allow you to use these varieties of adjustments across all models to allow for even more versatility.

The amount of information variables for devices does vary by gadget kind, but general, Telcordia generally requires for much less data and MlL-HDBK-217 and 217Plus require more. Nevertheless, some reliability prediction software program packages do not need you to get into all the data parameters and will use typical default beliefs, which allows you to carry out a conjecture with minimal input. Making use of the 217Plus MIL-HDBK-217 Reliability Prediction Methods 217Plus can alter failure price estimates centered on process grades. Process grade invoice discounting is found just in 217Plus and accounts for different elements that may impact device reliability such as the encounter of the design group and wear out. 217Plus also views the operating profile of your system and offers results in units structured on calendar hours - another differentiating aspect. MIL-HDBK-217 failing rate predictions are generally more pessimistic than Telcordia ánd 217Plus dependability predictions.

Nevertheless, this is variable and depends on the gadgets in your program. Choosing One (Or More) Dependability Prediction Requirements Unless you have got a contractual necessity to make use of a specific standard, the selection of the dependability prediction regular should become centered on your particular needs associated to the design in issue. Or, one of the reliability specifications may become more frequently used in your business.

Or, you may examine the specifications to figure out which one consists of the conditions and elements best matching your style. Ultimately, the choice of the dependability prediction model is up to you and can become made structured on your specific needs. You can furthermore combine and complement specifications. For instance, one popular method of carrying out reliability conjecture analyses will be to make use of MIL-HDBK-217, Telcordia, and the NPRD/EPRD sources together.

In this situation, you get protection of almost all gadget types utilized in item style. All dependability predictions criteria mentioned right here are broadly identified and accepted.

The option is centered on particular needs. There is certainly no ideal or wrong selection - the choice must be structured on which regular best matches your needs.

Calculating Failing Rates with Dependability Prediction Software program You can make use of reliability conjecture evaluation to assist in numerous elements of product style and advancement. Engineers have used dependability prediction analysis for several decades across the globe in a broad span of industries to help in the using ways:. Assessing the feasibility of a suggested design. Comparing design options for the most reliable choice.

Identifying possible reliability areas of concern. Performing What-If? Studies to figure out the effects of particular design modifications. Tracking dependability improvement. Dealing with product high quality problems in earlier design before they become problematic. Lowering the Cost of Poor High quality (COPQ).

Reaching contractual conformity requirements Therefore, no matter which method you select to execute your reliability prediction computation and analysis, you will obtain the benefits natural in including this method to your reliability and quality tool established. Using dependability prediction software to determine failure rates can make this procedure simpler and offers critical data for reliability needs. The greatest tools will even enable you to combine and go with standards, provide built-in component libraries, and enable you to view how design changes effect reliability. See how Relyence's reliability conjecture software can help with failing rate calculations - start a free trial today!